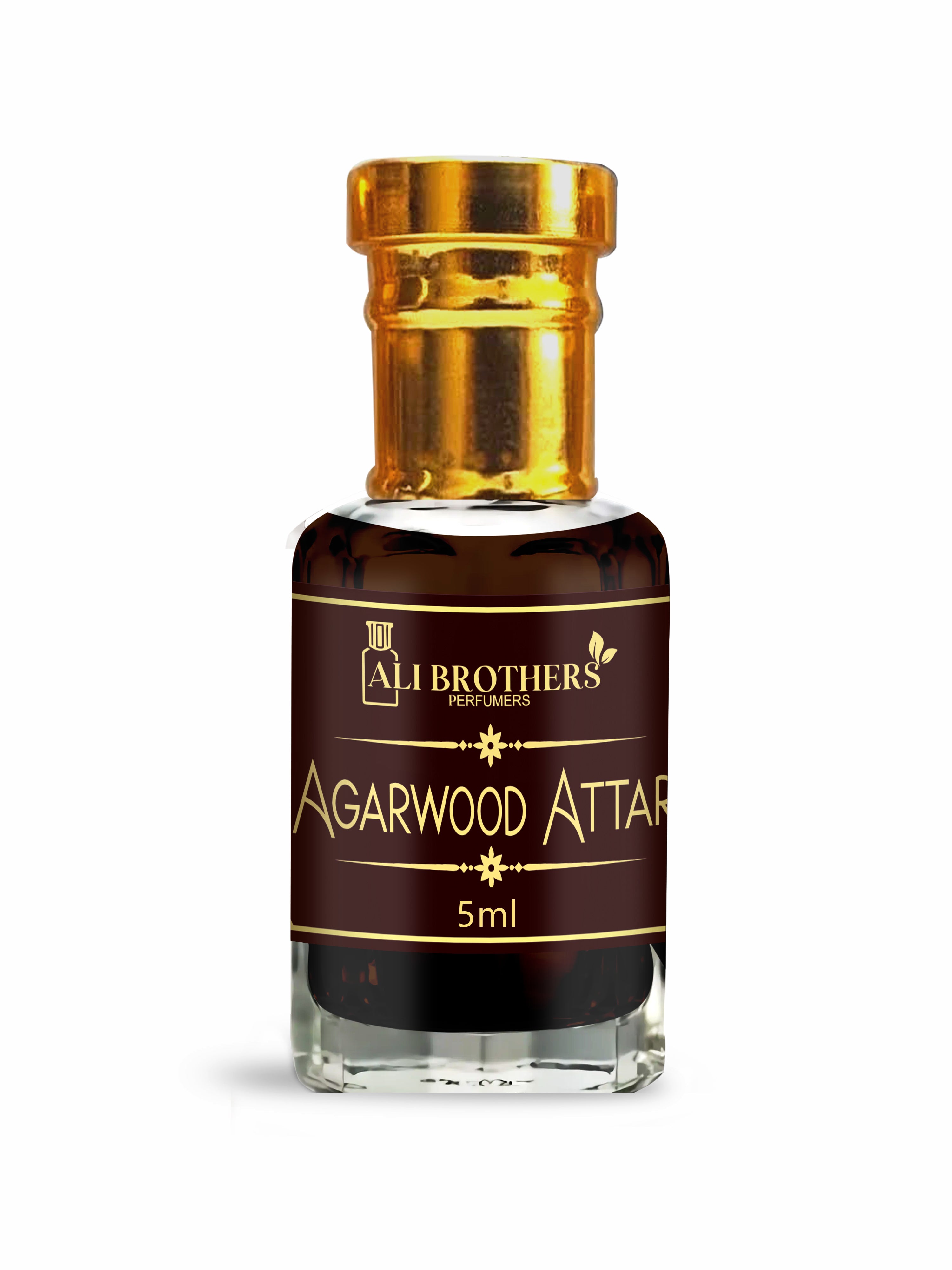

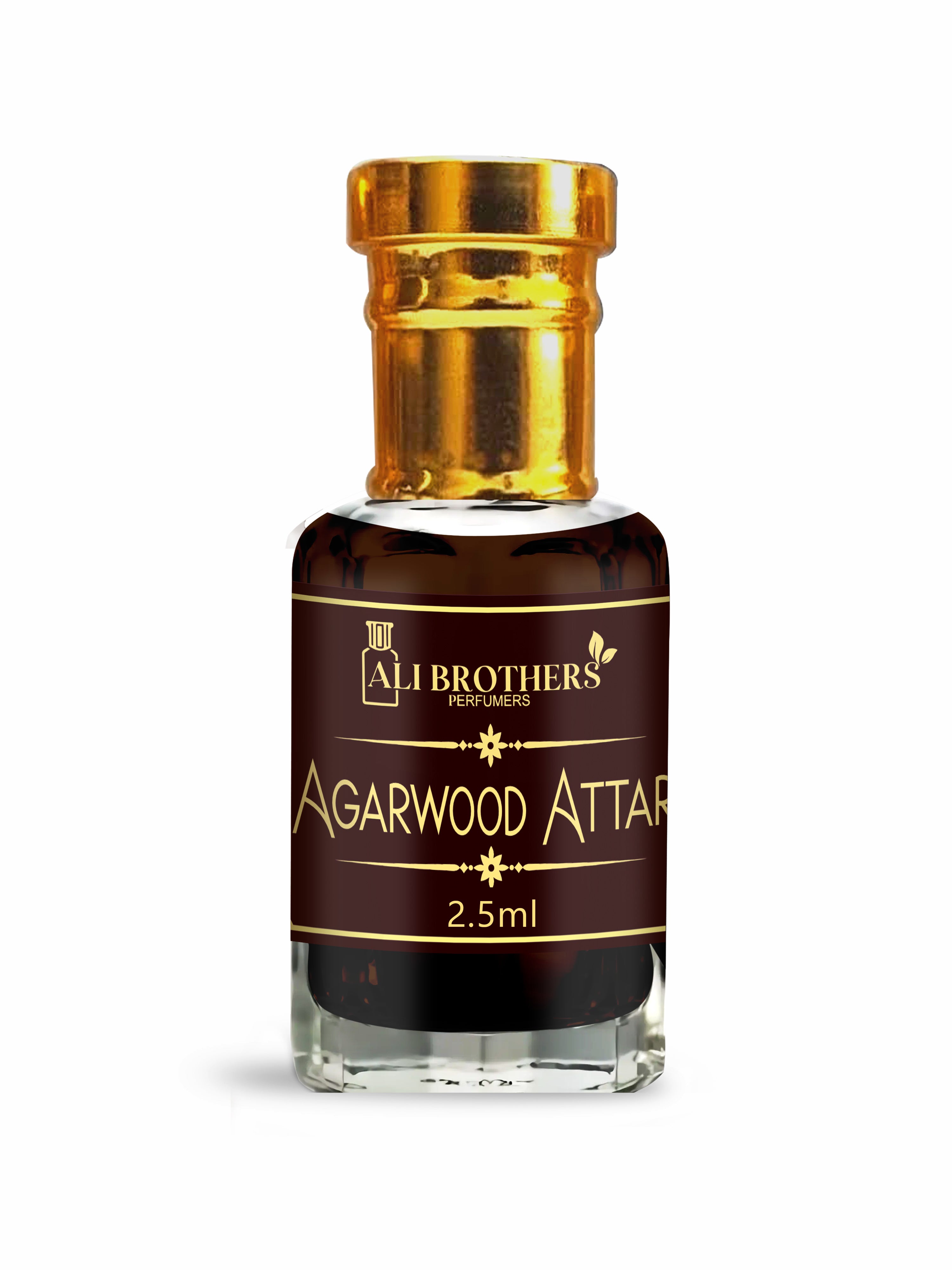

Agarwood attar is the most expensive attar in the world due to it being scarce as it takes hundreds of years for the resin to form from mold on the tree. It is extracted from the agarwood tree’s wood using extensive process of hydro-distillation method. It is a dark brownish liquid with a pleasing and intense aroma. It has a deep, earthy, musky, woody

and intense aroma and has warmed, purifying, balancing, deep woodsy & transcendent qualities. It is the base with pure sandalwood essential oil to create the purest form of agarwood attar.

Agarwood Powder in water are kept in a copper made still, a Deg. The lid(The Sarpos) of the still, is sealed with clay saturated cloth, sealed with a so called Komoni. Sandalwood oil is kept in the copper receiver(the Bhapka). The furnace is lit and controlled by adding more wood or cow dung cakes (or removing them). The scent of Agarwood is beared by steam with the help of the most skilled workers.The scent of the Agarwood in the steam infuses the sandalwood oil. Over several rounds of Agarwood distillation ,sandalwood oil is imbibed well with the smell of Agarwood.

The Bhapka containing the sandalwood oil is kept cool in a cooling bath or tank which continuously receives fresh cold water. Then the Digha halts the distillation process by wrapping a cold wet cloth around the body of the Deg. The Bhapka is now left to rest so oil and Agarwood water can separate. The water is then carefully poured away from the oil. The Agarwood water is then poured back into the Deg and fresh Agarwood Powder is added again. This process is continued until the desired quality of the attar is reached. Then the attar is poured into a leather bottle, which is ideally kept in the sunlight for some time to evaporate its moisture for the best result.

It is 100% pure and natural attar so it it much appreciated among aromatherapists and perfumers.

Recently Viewed Products

- From $28.57

- From $28.57

- Unit price

- per

- From $28.57

- From $28.57

- Unit price

- per

- From $28.57

- From $28.57

- Unit price

- per

- From $28.57

- From $28.57

- Unit price

- per

- From $28.57

- From $28.57

- Unit price

- per

- From $28.57

- From $28.57

- Unit price

- per

- From $28.57

- From $28.57

- Unit price

- per

- From $28.57

- From $28.57

- Unit price

- per

- From $28.57

- From $28.57

- Unit price

- per

- From $28.57

- From $28.57

- Unit price

- per

- Choosing a selection results in a full page refresh.